Stockpile volume calculations remain one of the most important, yet challenging tasks in mining and quarry. The site size, area of coverage, material type and safety factors all could potentially result in operations collecting subpar data. To effectively complete the task, operations need a combination of the right tools that enable them to measure stockpiles accurately, efficiently and fast.

For Chattanooga Tennessee-based Wingfield Scale and Measure these values are at the core of their business and promise to their clients. Over the past 85 years, they have grown to become a nationally recognized scale and data acquisition company, and today, they offer their customers innovative mapping and measuring services for surface/quarry work, underground mapping, structural scanning, real-time inventory products and drone services.

As the first scale company in the U.S. to complete accreditation to both ISO 9000 and ISO 17025, Wingfield holds a strong focus on its response time, reporting accuracies and on-site safety practices. Their mapping work reflects the true nature of how materials are stockpiled on the ground, as well as the base topography beneath the material – creating a true digital representation of the area being surveyed. This approach lends itself to accurate, repeatable, and prompt delivery of volumetric information to clients.

“90% of the work that we do requires multiple measurement platforms. Whether that’s a terrestrial scanner, total station, photogrammetry UAV, or LiDAR UAV, there are different tools that when used together, give you a better, more complete result.”

Hayes Wilkinson, UAS Certified Mapping Scientist, and Senior Aerial Mapping Specialist at Wingfield Scale & Measure

They attribute this success to a combination of surveying technologies, workflow and attention to data management factors that enhance both quality and accuracy.

Combining aerial and terrestrial data for better results

There’s no silver bullet when it comes to obtaining a complete data collection. Wingfield Scale and Measure is a data acquisition group and always recommends using the right combination of tools for the job.

For example, if your operation has half its piles under structures, it’ll be nearly impossible to survey without some sort of LiDAR technology.

“90% of the work that we do requires multiple measurement platforms,” says Hayes Wilkinson, UAS Certified Mapping Scientist, and Senior Aerial Mapping Specialist at Wingfield Scale & Measure. “Whether that’s a terrestrial scanner, total station, photogrammetry UAV, or LiDAR UAV, there are different tools that when used together, give you a better, more complete result.”

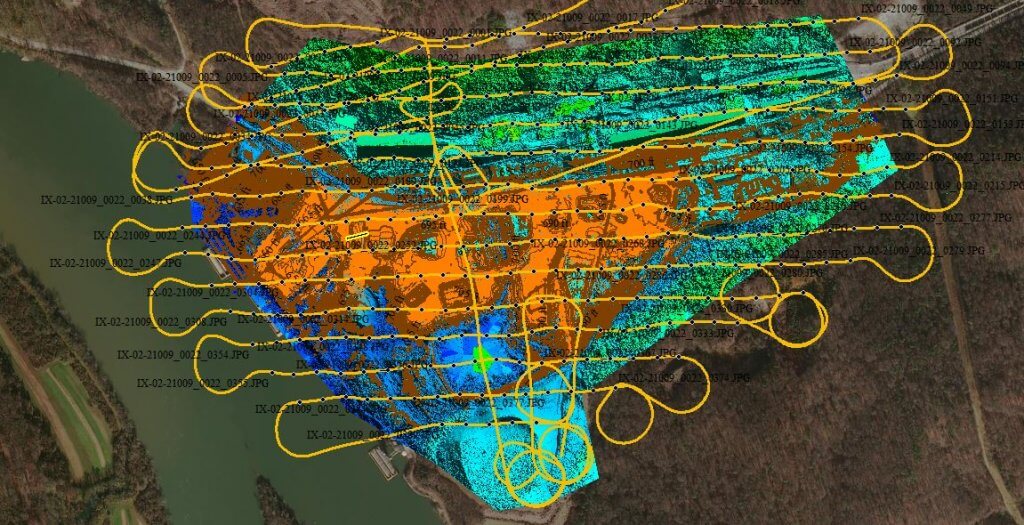

Wingfield Scale & Measure has used a variety of UAVs over the years, and recently added an eBee X fixed-wing drone and S.O.D.A. camera to its survey toolbox. The eBee X has long been used in mines worldwide for their ability to cover mid-to large-scale sites quickly and deliver highly precise photogrammetry.

Wilkinson adds that the eBee X has the ease-of-use and user-friendliness to hit high accuracy requirements with photogrammetry, while directly complementing and validating their LiDAR measurements to ensure accuracy in reporting.

On a recent survey for a cement plant, Wingfield conducted a stockpile survey using terrestrial equipment and the eBee X on a wide variety of stockpile sizes and materials, and was pleased with the results.

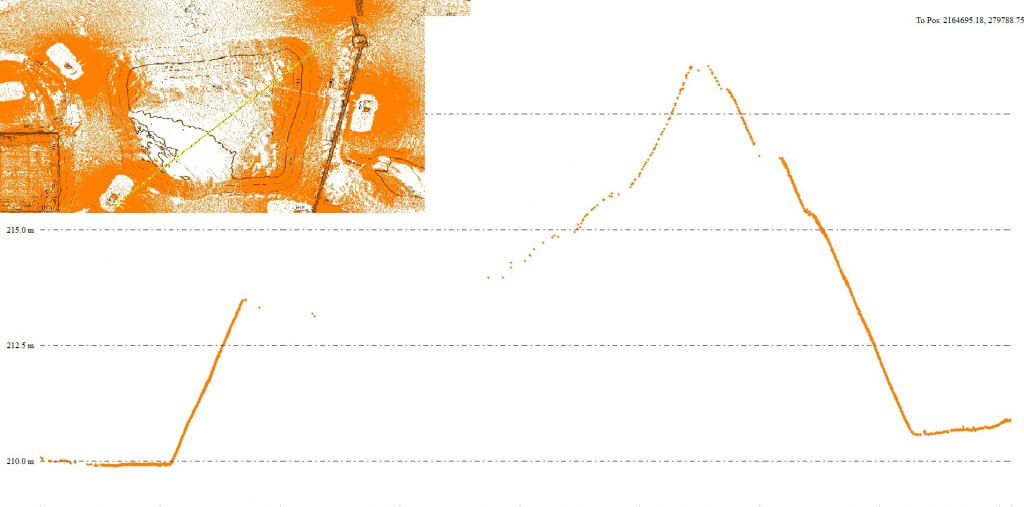

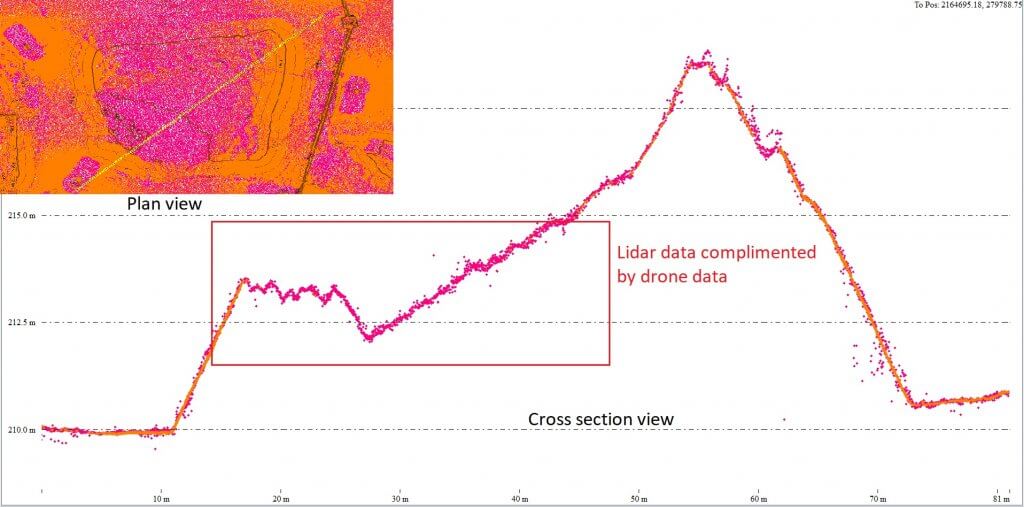

As seen in the comparisons below, the laser scan data and eBee X / S.O.D.A 3D data complement each other very well as the eBee data was able to fill in the areas which were not visible or inaccessible in the terrestrial laser scan data, due to the geometry of the stockpile.

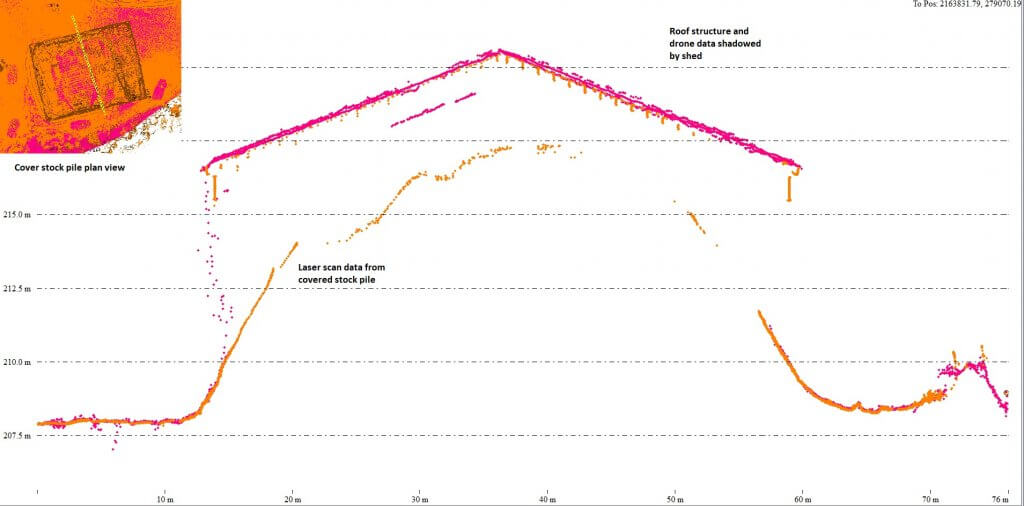

In the opposite effect, the laser scan data complements the eBee data in visually obstructed areas as shown below, where this stockpile was covered by a shed roof.

In this example, both types of data were easily merged producing a rich and accurate data set combination which gives inventory managers greater control over the volumes and resulting KPI calculations.

Required accuracy vs material

Laying the groundwork for efficient collection is first understanding the accuracy that’s required for the type of material being measured. This accuracy is important to site supervisors conducting weekly reporting and monitoring of monthly KPIs.

“If you’re dealing with a high-value material like gold ore, a 5% or 10% swing in volume accuracy can have huge downstream effects on a company’s books and operational decisions. Even with lower value materials like gypsum or clay, the same holds true – accuracy affects the bottom line,” says Wilkinson.

As a result, there are very different realms that you’re working in as far as how different and how tight the data requirements need to be – and are required to be.

Material reflection

The reflective properties of the project material surface are very important when it comes to noise versus accuracy. The surface color of a stockpile changes dramatically across its form, while the surface texture remains the same.

When processing in photogrammetry, it is important the camera can adjust to this differentiation of light reflectance and give a good overall white balance correction, so as not to overexpose the images and produce noise in the data.

“This noise can equate to false detection of extra volume if not carefully filtered or removed,” says Michael Blake, Product Manager, Arnold. “Depending on the type of material, these false volumes can fluctuate the weekly reports and monthly KPI’s which can determine a company’s strategic, financial, and operational achievements.”

This volume difference can be exponentially more evident on high-value materials like gold, silver, and copper.

Workflow enhances accuracy & efficiency

Thanks to the ease of use of the eBee X platform and intuitive eMotion flight planning software, the Wingfield team also realized an enhanced workflow from flight planning to post processing.

It’s a natural step from eMotion to Pix4D to produce final rasters and vectorized data and this workflow results in less work. With other platforms, it’s common to need additional third-party software at this stage to produce georeferenced data and project files.

Taking their data processing a step further, Wingfield typically brings their drone and LiDAR data together in third-party software and filters it, removing any noise before performing cut and fill calculations.

This additional step enhances the richness of the data the drone provides while giving a better overall accuracy to end calculations for monthly KPIs.

Michael Blake, Product Manager, Arnold

Much of the filtering done in the third-party software can be automated. Wingfield has custom-tailored workflows to streamline certain aspects of point cloud filtering and preserve consistency from one dataset to another. Additionally, all newly acquired data is compared back to previous surveys to make informed decisions about where to delineate stockpiles, and how to reuse historical bases and data. A critical and experienced eye is applied to every stockpile inventory and topographic survey, something that is not provided by many cloud-based Structure from Motion (SfM) photogrammetry solutions.

“This additional step enhances the richness of the data the drone provides while giving a better overall accuracy to end calculations for monthly KPIs,” says Blake.

Data quality control

Wingfield Scale & Measure compared their new eBee X to their DJI Phantom 4 with an aftermarket PPK kit to see if there were any observable differences in data quality. There were four areas where the team immediately noticed differences between the technologies.

Image quality

The quality of various point clouds can be assessed by observing point density and noise. Generally, point density is very high in the case of terrestrial laser scanning point clouds, however, the earlier comparisons show that the UAV’s less dense point clouds achieve similar results. While UAV point clouds provide less detail than a terrestrial laser scanner point cloud, there is still enough detail provided for most typical survey applications.

When Wingfield compared outputs from their UAVs, the team noticed the images from the DJI Phantom 4 PPK stock 20 MP sensor (same camera as the P4P-RTK) had more noise and poor color balance in comparison to the eBee X with S.O.D.A 3D. This can equate to a lot of blur in the images and give poor orthomosaic quality and more point cloud noise which has to be filtered.

While the eBee X with active RTK delivers high-precision accuracy down to 1.5 cm without requiring GCPs for georeferencing, their use is still recommended to verify data quality. As a result, significantly fewer checkpoints need to be laid and for the size of Wingfield’s project, the team would only need three to five GCPs for data verification, which of course increases safety and saves time.

Flight time

Fixed-wing drones are estimated to be 80% quicker than traditional terrestrial methods—saving valuable time by collecting the data needed quickly and efficiently from a single point.

From data acquisition to battery changes and transition times, fixed-wing drones also require fewer flights than multirotor platforms. In this comparison of a 194-acre aggregate site, the eBee X covered the entire area in a single flight with enough battery life in reserve to map a similar-sized site 5 more times under ideal flight conditions. It took two flights with the DJI Phantom 4 PPK to cover this one site.

Georeferencing

The overall Root Mean Square (RMS) was a lot larger with the DJI in comparison to the eBee. GCP points were needed to correctly georeference the Phantom 4 RTK data with the LiDAR data, whereas the eBee X data aligned perfectly with the LiDAR data – with no GCP points need.

Since November, Wingfield has geotagged ~20,000+ images taken by the eBee X with CM level accuracy with a > 99% success rate. Hayes adds that in comparison, the third-party PPK GPS unit for their multirotor is good and simple to use, but less consistent in field and post processing workflows.

The process of collecting point data in the field with the RTK-enabled eBee X, means operators are more efficient by spending less time in the field, and safer by not having to traverse potentially hazardous terrain to lay numerous GCPs. Thanks to good photogrammetry, only a couple of checkpoints are required around the site as a best practice to ensure the RTK/PPK workflow is working correctly.

Post processing

Data processing with photogrammetry software can be time-consuming, depending on the quantity of data captured and computer hardware being used. However, by using the IMU and “direct-in-flight geotagging” data from S.O.D.A. 3D in conjunction with PIX4Dmappers’s accurate geolocation and orientation calibration method, you can accelerate the initial calibration stage, resulting in a time savings of up to 35-40%.

“What’s more, we found no compromise to accuracy,” adds Blake. “Vegetation and water bodies also reconstruct and recompute much better, giving more detail and contextual information to the dataset.”

See our previous blog post on achieving faster initial processing for more information.

As an added data security measure, Wingfield completes all their processing on a local PC and no images are uploaded to a remote/cloud-based server, which is a common data management consideration for clients with sensitive job sites.

For large mines and quarries, fixed-wing drones represent a valuable method which surveying teams can reduce their data collection workloads. Therefore, this allows organizations to reduce their staffing costs, offer more competitive pricing and/or complete more projects within a set time.

Additionally, drone acquired data such as orthomosaics can lend additional benefits to open pit operations, mine design, site planning and many other areas.

While tracking stockpile inventories remain one of the most important tasks in mining and quarrying, fixed-wing drones, and the efficiencies they deliver, are minimizing what used to be a challenge. Their ability to rapidly provide photogrammetry and high-resolution point clouds that enhance LiDAR enables quality management of stockpile surveys with greater speed, efficiency and accuracy.

For a closer look at comparative LiDAR and photogrammetry data, watch for our Wingfield Scale & Measure case study – coming soon!

Sidebar: Controlling for environmental factors

Another key factor to take into consideration during data collection is the proper setup for ground control and changing lighting conditions. This step can easily get overlooked by busy personnel and results in gathering and processing subpar data right out of the gate.

Mines are highly active environments and a lot can change over a month. Hayes recommends doing a quick check before each flight to ensure ground control points are cleared, checked and ready to go with their placement throughout the site.

The lighting at the time of your aerial survey can also affect your data collection and it’s worth noting that results can vary depending on your drone platform.

“One thing I’ve noticed from personal experience with both platforms is with the eBee, it’s much easier to control for changing lighting conditions than with the Phantom,” says Hayes. “If you lock your exposure, and it’s too bright or too dark to account for changing light conditions, you can get some wonky results.”

The eBee’s exposure settings float between a constrained range by default that’s been precisely refined to allow the shutter speed to be fast, yet still, let enough light in.

“With the Phantom, sometimes if you let it float on an automatic mode, the shutter speed can be way too slow and you’ll get a blur to the images which isn’t ideal,” adds Hayes.